July 20, 2022

Design-To-Cost, long considered as a technician’s operation, is now part of the toolbox of cost control and value creation tools of the quasi-total manufacturing leadership teams. Resulting from the Value Analysis, this process gives rise to the development of multiple variants and extensions, the most convincing being undoubtedly the ReDesign-To-Cost.

Design-To-Cost advocates a vision of integration, seeking savings by aligning with the right customer need. Simultaneous engineering breaks the implicit distribution of roles where resources dedicated to product design are concerned with customer value, while cost control is the responsibility of Supply Chain actors.

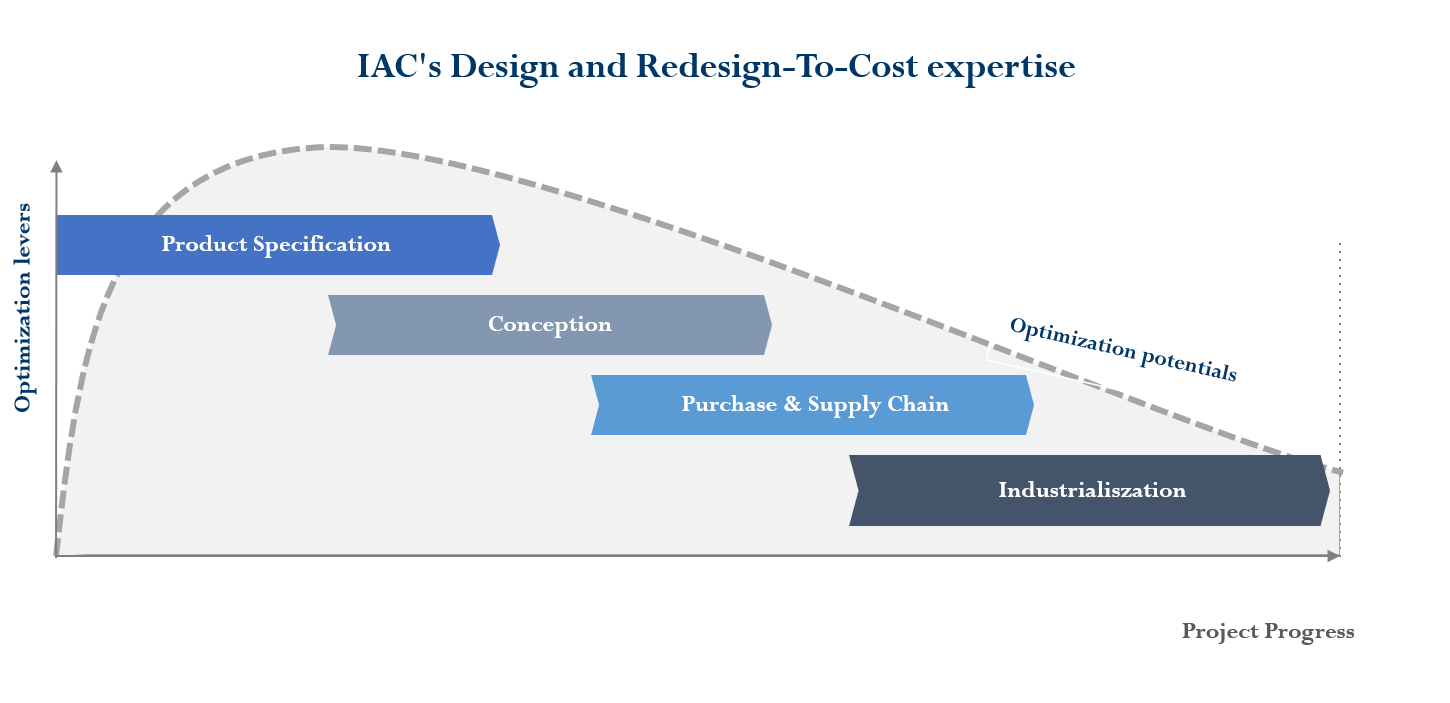

This approach makes it possible to activate the levers of specifications, product design and its industrialization in the broad sense to tackle all the direct costs of a product.

Unlike most Cost Killing techniques, (Re)Design-To-Cost has the advantage of preserving or even improving the value perceived by the customer

Our teams are the players in the creation or restoration of product competitiveness by fully activating the levers of cost reduction and innovation

Our OPQCM certification guarantees our clients concrete results and integrates techniques related to new industry challenges:

For example, an ecodesign approach can be implemented in parallel, so that a product already on the market incorporates environmentally friendly features. A manufacturer will be able to review his product policy and the associated marketing promise while increasing margins and perceiving value.

From a financial point of view, Design to Cost or Redesign to Cost projects can, under certain conditions, reduce costs by 20% to 30% (depending on the sector). Thanks to the deep questioning of specifications and technological choices there are porjects that have exceeded 50 % of earnings. Reducing environmental impact and improving quality and timelines are some of the associated interests with this approach.

Many companies also choose to relocate part of their production. The application of this methodology then makes sense because it makes it possible to break down costs and thus identify the functions to be retained, improved or eliminated. There are many examples of successful relocations. Let us mention the case of Atol, SEB or Veloscoot. These successful relocations require a redefinition of production processes to reduce manual interventions to a minimum and thus cancel the competitive advantage of BCCs (see our publication “Relocation in France: Yes we Can!“)

Thanks to their multi-sector experience, our experts offer you the benefit of bold solutions that have proven their worth in other projects. Their experience also guarantees the commitment of all stakeholders. Indeed, a new process only works if it integrates the constraints of all stakeholders.

July 20, 2022