Role of Nuclear Energy in Achieving Net Zero Emissions

Net zero emissions policies are crucial for addressing the impacts of climate changes. Many countries and organizations have set ambitious goals for achieving carbon neutrality by 2050 or earlier.

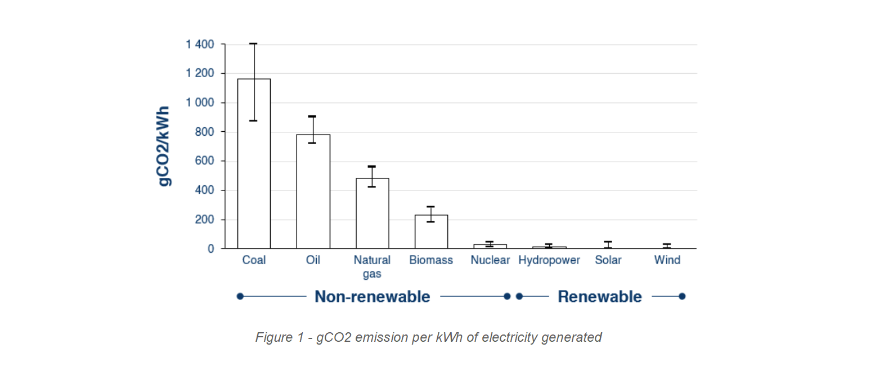

Compared to other energy sources such as fossil fuels or renewable energies, nuclear energy has several advantages. As illustrated in Figure 1, nuclear power plants generate electricity without direct CO2 emissions during operation: some CO2 emissions (few gCO2/kWh) are associated with construction, mining of uranium, and fuel processing; however, these emissions are relatively low compared to fossil fuel sources.

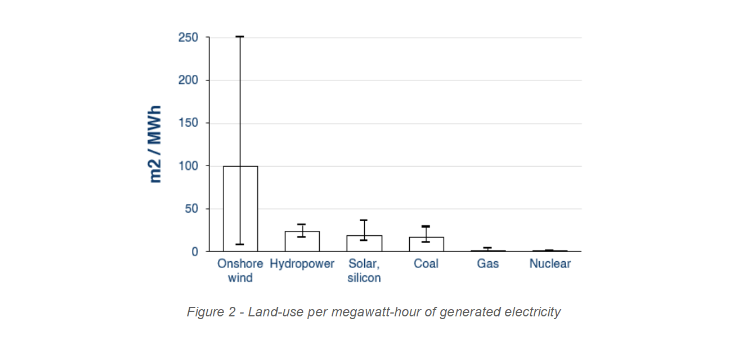

The generation of electricity produced by nuclear power plants is reliable, and it can be controlled and made available on demand, independent of all environmental conditions. Moreover, as visible in Figure 2, the land-use per megawatt-hour of generated electricity is lower than 1 m²/MWh: the lowest compared to other energy sources.

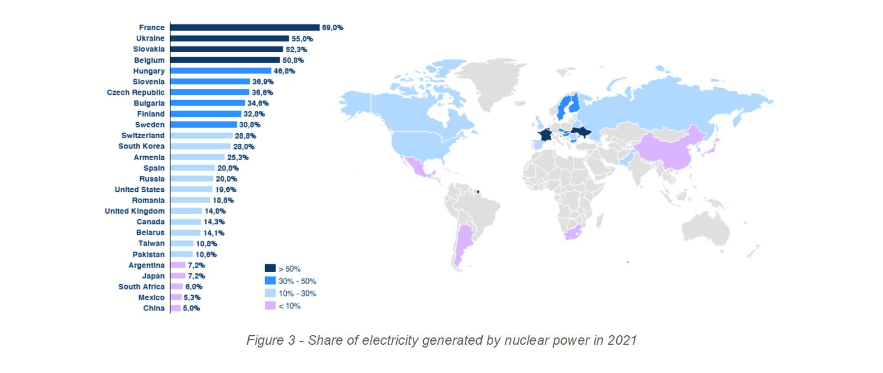

Many developing countries, such as China and India, are expanding their nuclear energy programs as a way to meet their growing energy demands while reducing carbon emissions. According to the International Atomic Energy Agency (IAEA), there are currently 52 nuclear reactors under construction worldwide, with 18 located in China and 8 in India. Figure 3 shows the share of electricity generated by nuclear power in 2021. France, Ukraine, Slovakia, and Belgium are the countries which most rely on nuclear energy, and nuclear sources provide more than 50% of their electricity.

Nuclear energy also poses significant risks and challenges, such as the potential for nuclear accidents and the long-term storage of nuclear waste. Additionally, while the OPEX costs for nuclear power plants are generally in the range of a few cents to several cents per kilowatt-hour generated, the CAPEX costs can range from a few hundred million dollars to over $10 billion, depending on the reactor technology, capacity, and site-specific factors. On top of that, the construction of a nuclear power plant can take around 10-15 years from the initial site selection to commercial operation.

EPR 2 : benefits of standard design

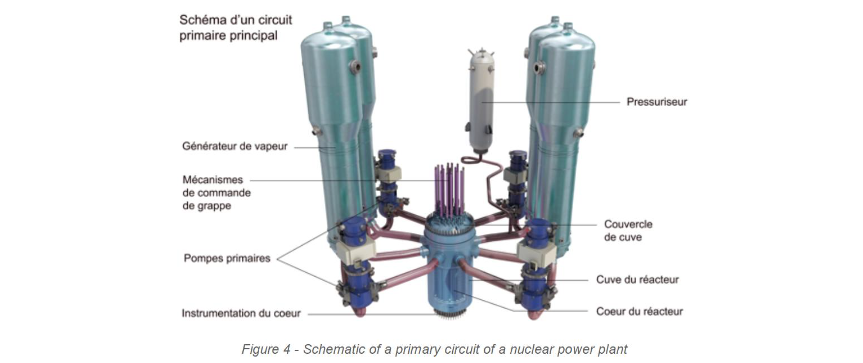

In response to the exponential growth in energy demand and the need to achieve carbon neutrality objectives, the French energy company EDF has developed a new generation of the European Pressurized Reactor (EPR) and has done a first order for the construction of 6 identical reactors. Figure 4 shows the schematic illustration of a primary circuit of a nuclear power plant.

Based on the technology and design of the first generation of EPRs, this new EPR 2 leverages the experience of a large worldwide park of nuclear reactors to create a standard design that offers a wide range of benefits on costs, quality, and lead-time.

Main benefits on costs :

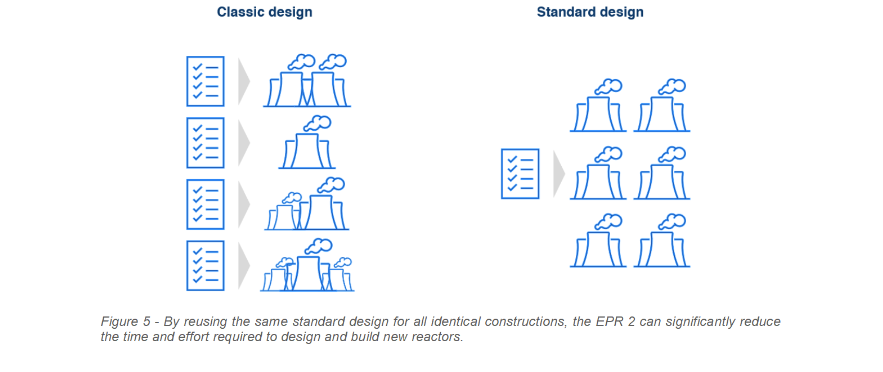

- One of the main advantages of standardization is the reduction in redevelopment and design efforts. Indeed, to ensure high safety standards, each design modification triggers important qualification and certification efforts. This is particularly important in the nuclear sector, where the development and design processes are highly complex and time-consuming. By reusing the same standard design for all identical constructions, the EPR 2 can significantly reduce the time and effort required to design and build new reactors (illustration in Figure 5). Moreover, the standard design secures the supply chain and leverages the procurement costs with scaled savings on materials and components, which further reduces costs and delays and allows for supplier investments.

- Today, according to a governmental audit, the cost of the three twins of EPR2 is estimated at around 51.7 billion euros, while the cost of the Hinkley Point C twin in the UK is estimated at 30 billion euros. This represents a 43% cost improvement per reactor.

Main benefits on quality :

- Standardization also allows for leveraging a reliable supply chain to ensure a high level of safety based on past experience. By working with suppliers over a long period of time, providing them with a long-term visibility of up to 20 years, and using a stable, standardized technical design, the EPR 2 can improve supplier performance and reduce the risk of delays or quality issues. Moreover, this allows for serial production, even with low volumes.

Finally, the EPR’s standardization is also accompanied by a commitment to quality through process control, continuous improvement, and the reduction of non-conformities. This commitment ensures that the EPR 2 is a safe, reliable, and environmentally sustainable solution to meet the growing demand for energy while achieving carbon neutrality objectives.

Success conditions for standardization in the nuclear industry

Standardization is often acknowledged as a way to reduce costs, improve quality, and increase efficiency in industries such as manufacturing and construction. However, in the nuclear industry, standardization can also pose some challenges that need to be tackled to ensure safe and reliable operations.

One of the common misconceptions associated with standardization in the nuclear industry is the belief of potential for monopolies of suppliers who have developed or qualified specific technologies or processes. The reduced supplier panel can limit competition and innovation, leading to higher costs and reduced quality. In addition, relying on a single supplier can create a dependence that may be difficult to break, especially if that supplier becomes unavailable, uncooperative, or sees its performance decreasing. However, this perception overlooks the fact that standardizing the design actually presents an opportunity to increase multi-sourcing while maintaining the same number of suppliers.

Obsolescence is another risk associated with the large scale purchasing of standard references. Indeed, in the nuclear industry, regulatory requirements can change rapidly, making some components or materials obsolete. This can result in significant waste and cost if the obsolete parts are not properly managed, or if replacements must be sourced from a single supplier. However, standardization reduces the number of references to handle, allows for a lean obsolescence management, and leads to a beneficial impact on a larger portion of the portfolio when actions are taken to update a reference.

Finally, to mitigate these drawbacks, it is important for nuclear companies to carefully supervise their supply chains and maintain close relationships with their suppliers. Alongside the benefits, standardization can also bring some challenges of which it is important to be aware and know how to address them to minimize their impact. This includes developing contingency plans for supplier disruptions and monitoring regulatory changes to ensure that components and materials are kept up-to-date.

Des résultats tangibles à chaque mission

July 17, 2023

The space industry’s path to a sustainable future

July 4, 2023

Measure R&D performance

June 8, 2023

The digital patient pathway

June 7, 2023

Charging stations

Design-for-resiliency is the practice of incorporating resiliency concepts into the design of products, systems, and processes.