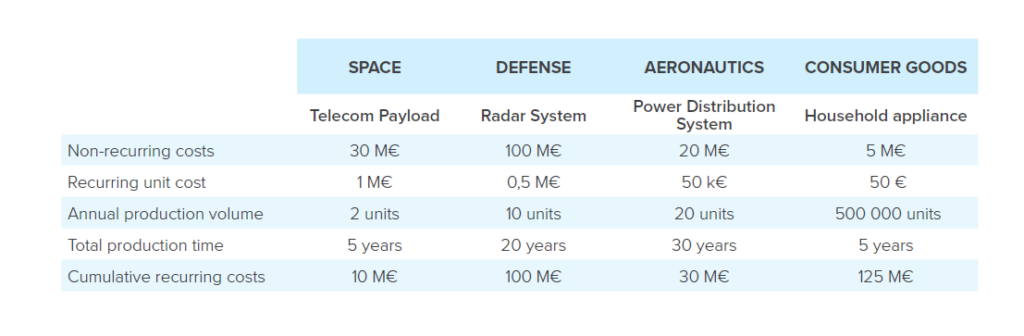

In industrial sectors with low production volumes, such as space, defense and aeronautics, medical imaging or high-tech equipment, the amount of non-recurring costs spent by an industrial on a new program is frequently equivalent to or greater than the sum of recurrent manufacturing costs accumulated over the entire production life of the equipment.

Despite this situation, companies often devote less attention to securing their development costs, compared to efforts dedicated to optimizing the recurring costs of their products. Several factors explain this state of affairs

- In the absence of well-established time reporting methods

- Few feedback and root cause analysis exercises are actually conducted

- More and more sophisticated predictive methods are now available

- Study costs are sometimes knowingly underestimated at the beginning of a project

- Finally, it should be pointed out that the optimization of study budgets remains a taboo

The table below provides some representative orders of magnitude by sector of activity.

Tangibles results at each mission

July 17, 2023

The space industry’s path to a sustainable future

July 4, 2023

Measure R&D performance

June 19, 2023

Standardization perspectives of nuclear plants

June 8, 2023