Slow and Steady Wins the Race

Keeping a product launch (Time-to-Market) calendar can prove extremely challenging and depends on a combination of different strategies. All industrial professionals have on one occasion or another experienced a rushed product development, either to meet the deadline of a trade fair or take advantage of a seasonal sales opportunity. And there is not a single R&D professional who has never had a confrontational meeting with a sales department colleague, because today’s products meet yesterday’s needs and tomorrow’s products will not be released until the day after that.

Unfortunately, the impact of bad time-to-market management is far from insignificant. For industrial companies facing deadlines because of trade fairs or seasonal market opportunities, rushing a product launch inevitably leads to higher costs and diminished economic performance. Product features are left out, negotiations with suppliers are cut short and existing technical solutions are reused without being optimized. Of course, there are those who would rather secure their profit margins and favour the product’s performance over deadlines, but pushing back a launch date has a negative impact on development costs, gives the competition additional time to gain a foothold on

the market and increases the chances of there being a discrepancy between your product and your customers’ expectations, which might have evolved during that extra time.

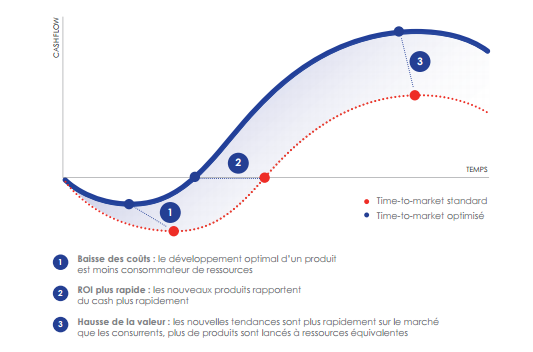

On the contrary, compressing your Time-to-Market calendar for a new product certainly is a good way to keep non-recurring costs down, reduce your time to return on investment and show greater adaptability to market shifts than your competition (see figure 1). So, how do you design a strategy to help you accelerate new product launches? What parameters do you need to focus on and what challenges will you be facing?

The first key to managing and improving your time to market is to adjust your organization by providing it with a consistent product strategy, the right processes and effective operational tools.

Some of our clients even go further than that by developing modular product ranges. The goal is to invest money at the beginning of the process and be in a capacity to launch more products in the long run, while keeping recurring and non-recurring costs down.

An organization that focuses on time-to-market optimization invariably keeps a simple product development roadmap, with clear priorities.

Experience has shown that initiating more projects doesn’t translate to more products reaching the market — quite the opposite.

The reasons are well-established: divided resources, priority changes during development, impossibility to allocate resources on objective criteria.

Some effects are clearly visible: delayed launches, conflicting alternatives, a sense of urgency, etc. Others, not so much: loss of employee efficiency, loss of information, difficulty to implement a comprehensive cost optimization strategy.

Therefore, it is the Board of Directors’ responsibility to define a roadmap, based on economic and strategic considerations, the company’s competitive context, and their precise evaluation of corporate resources.

Once those foundations have been laid, project leaders can then start assessing their product development processes, without forgetting to compartmentalize: a minor cosmetic redesign should not be treated on par with a breakthrough innovation.

The main challenge in terms of Time-to-Market at that point is to break through those glass walls that stand between departments: sales and R&D, R&D and production, procurement and the rest. All companies, including the most high-profile corporations, suffer from a lack of communication between departments: customer needs are insufficiently or inaccurately reported, issues regarding manufacturing are only addressed at the end of the process, procurement is involved too late in the definition of technical solutions, the list goes on.

Additionally, some companies compound the issue by implementing very standardized phase-gate processes, which for instance require formal approval before any step can be initiated — including design reviews, Go tooling or any other major project milestones. Most of the time, taking a more flexible approach, eliminating unnecessary approval processes and shifting to a more pragmatic approach, can greatly increase efficiency.

Building a process that involves everyone at the right time, where information flows freely and delays can be compensated quickly, requires all employees to question their methods. Behaviours and work patterns are sometimes deeply ingrained, but promoting information sharing can make old boundaries disappear.

The last step, once the product development strategy and associated processes have been implemented, is learning to work more efficiently.

As we saw it earlier, optimizing your development processes yields greater and earlier commitment of all departments to R&D, which is usually the core of most product development projects. Managing more collaborators with greater efficiency requires practical tools and methods. The development phase must be limited in time to encourage focused efforts on high-value added tasks. The best way to go about this is to use visual management tools and hold short, but regular meetings with the entire team — the so-called stand-up meetings, which originated in start-up companies.

However, the terms of these meetings need to be tailored to reflect the company’s cultural identity and the project leader’s personality. A very directive system is just as possible as a more participative approach, where employees take turns leading every meeting.

However, for a long-term perspective, the most effective tools are technical rather than organizational.

Industrial companies that develop their ranges based on a modular concept systematically outpace even the most ambitious calendars set by competitors carrying traditional product ranges.

Modular design consists in breaking down products by function, then designing a module — i.e. functional unit — for each function, to cover the entire scope of features.

The point for industrial companies is to be in a capacity to introduce a growing number of products on the market, without having to change more than one or two modules, instead of starting from scratch every time.

We have seen an example of this with one of our clients, a company that designs and manufactures air compressors for industrial sites and shipyards. The goal was to launch 100 different models over the following 10 years, as opposed to one or two models a year previously!

So for each element type (pistons, cylinders, engines, housings, etc.), we have determined the variety of parts necessary to build the entire range and offer optimal solutions in terms of technical performance. We carried out a cost assessment and drew up a development calendar. The conclusion was that 81 basic modules were enough to develop 100 different products, when initially each new product was made up of 10 unique functional elements.

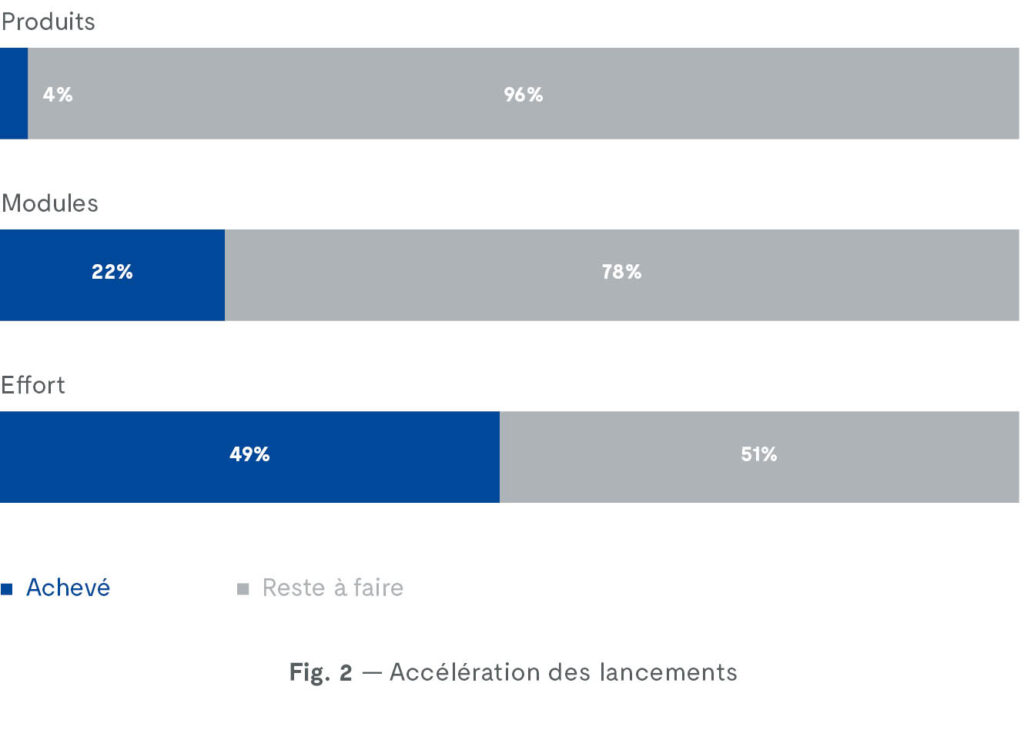

Our client then designed the modules that were needed for the first products. So after just two years, the first four compressors were launched on the market. But the pace of the releases will pick up in the years to come, as new models will use increasingly more existing modules. Figure 2 below shows that with only 4% of the range already on the market, 22% of the modules have been designed and almost half of the R&D efforts have been made.

Tangible results at each mission

July 17, 2023

The space industry’s path to a sustainable future

July 4, 2023

Measure R&D performance

June 19, 2023

Standardization perspectives of nuclear plants

June 8, 2023